Products

Bulk bag

Publisher : Telink Industrial

Bulk Bags or Flexible Intermediate Bulk Containers (FIBCs), Jumbo bags, Super sacks, Ton sacks are an economical and efficient way to package, store and handle products. Every bulkbag has four loop handles on each end for easy handling, filling and dispensing. Dependent on size, each BulkBag can hold approximately 2000-3500 pounds of material.

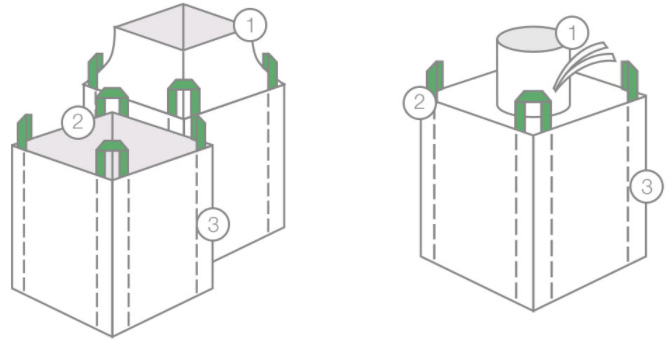

Duffle-Top or Open-Top Bulkbag |

Spout-Top Bulkbag |

| 1. Can be used for a large variety of applications such as: refractory products, quarry materials, sod, plastic extrusion etc. 2. Full open top that is tied after filling 3. From small sizes (25¡åx25¡åx29¡å) to large sizes (36¡åx36¡åx64¡å) |

1. Designed with a variety of spout sizes, it is used in applications where the manufacturers fill each bag through a funnel type system

2. The products that this bulkbag is usually used for are powdery substances: line, talk and diatomaceous earth.

3. Sizes from 34¡å tall to 36¡åx36¡åx54¡å

|

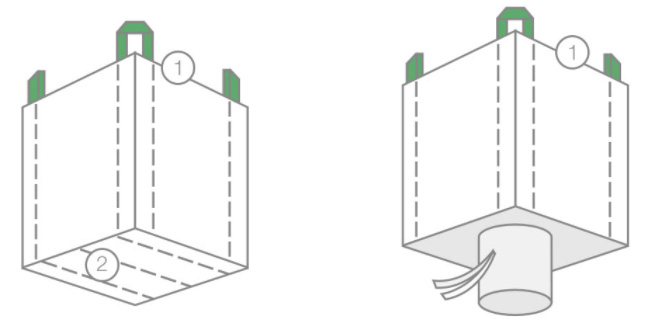

Plain-Bottom Bulkbag |

Spout-Bottom Bulkbag |

| 1. Used for applications that do not require a content emptying mechanism 2. Fully stitched bottom |

1. Used for applications which require a bottom content emptying mechanism |

There are many common types of FIBCs available in the market place. The most commonly used bulk bags are constructed as either a U-panel or circular construction.We offer a varitey of constructions, such as:

U-panel

Circular/Tubular

Baffle

Four Panel

FIBCs are also constructed based on their application. Whether it is being used for food grade, UN rated bags or multi-trip bags, the application is as important as the construction. Common FIBC applications are as follows:

Food grade bags

UN rated bags

Multi-trip bags

Chemical bags

Conductive or static dissipative bags

Valve bags or liquid bags

Each bag has a specific fabric required due to their application. Some bags require antistatic qualities, others do not.

Type A Fabric - No electrostatic protection.

Type B Fabric - Surface breakdown of <6kV.

Type C Fabric - Electrically conductive or groundable.

Container liner

Container liner Standard container liner

Standard container liner